Should Cost estimation for mechanical parts like Sheet metal, plastics, PDC, cables, assembly & packaging.May direct support personnel and/or partner organizations in the preparation of detailed design, design testing, prototype fabrication, and production tooling. Evaluates reliability of materials, properties, designs, and techniques used in production. Leads and/or assists in architecture development and assessment. Conducts feasibility, design margin and validation analysis and empirical testing on new and modified designs. When benchmarking competitor products, when preparing sales price analysis towards the customer, and when sourcing and negotiating prices with suppliers, you represent the results of your analyses,ĭesigns, analyzes, develops, modifies and evaluates materials, mechanical systems, equipment and packaging. You will work on a project basis in interdisciplinary teams (including research and development, manufacturing, purchasing, controlling) and also represent costing results across divisions. You will use the existing knowledge base on manufacturing and material costs and be responsible for expanding and updating it with regard to new technologies and innovations. BU/PT management, plant and purchasing, also in an international environment. You derive recommendations for action and represent these to. You will independently develop alternative solutions as well as the best possible process and product costs independently of the plant and supplier. With reference to intensive technology and supplier scouting, you identify and evaluate potential savings through changes to design, specification or manufacturing process.Įspecially for the early phases of the product development process, you will independently determine target costs including shadow calculations.

Initial Graphics Exchange Specification, ANSI file format.You are responsible for the holistic methodical and cost-structure analysis of mechanical components ((plastic, aluminium die casting, stamped, drawn, bent parts).

Magmasoft jobs software#

Magmasoft jobs free#

To learn more about our precision casting services, please see the following table or feel free to contact us directly.

Magmasoft jobs iso#

Our ISO 9001 certified facility guarantees the utmost quality of our products, meeting many high industry standards as set by the ASME and ASTM. We also offer a wide range of non-destructive testing (NDT) from our facility, including die penetrant and ultrasonic testing, as well as magnetic particle inspection. Our vast array of equipment includes two 12,000 pound coreless induction furnaces, five sand mixers, 19 element chemical spectrometer, a carbon and sulfur determinator, among other advanced casting machinery. We cast all grades of ductile and grey iron to create components of a variety of sizes, including widths up to 180", lengths up to 474", and weights up to 28,000 lbs.

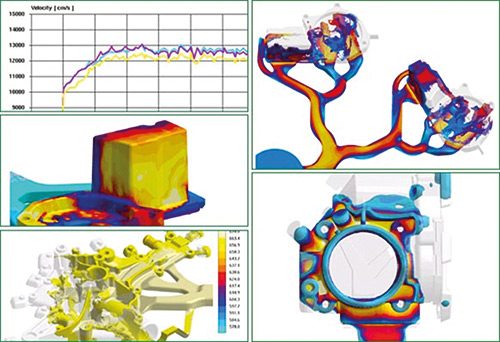

At our jobbing foundry and job-shop, we provide flask and flaskless no-bake sand casting, utilizing MAGMASoft Software for solidification analysis. At Glidewell Specialties Foundry Co., we take pride in our 5 decade tradition of providing high precision casting services.

0 kommentar(er)

0 kommentar(er)